RFID technology applied in a warehouse and logistics

- Share

- Issue Time

- Apr 3,2023

Summary

Agility and efficiency in warehouses are vital for their smooth operation, and one of the latest innovations they now have is RFID technology. Barcode technology has evolved notably in recent years giving rise to RFID (Radio Frequency Identification) technology. This system reads the identification codes through the use of radio waves, and makes them easier to read.

Agility and efficiency in warehouses are vital for their smooth operation, and one of the latest innovations they now have is RFID technology. Barcode technology has evolved notably in recent years giving rise to RFID (Radio Frequency Identification) technology. This system reads the identification codes through the use of radio waves, and makes them easier to read.

We will focus below on analysing their potential, characteristics and main advantages and disadvantages in their application in warehouse and logistics tasks.

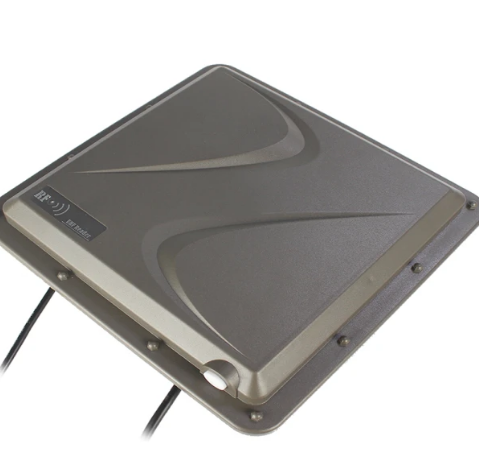

RFID (Radio Frequency Identification) is a technology that is able to transmit the data stored in a microchip through radiofrequency signals. It includes a defined protocol that stores and recovers information remotely, using tags, cards, etc.

RFID is ideal for the processes of warehouses or distribution centres, as the functions performed in them are always related to products and goods that have tags with necessary information. With this technology it will be simpler to monitor goods and know their origin and destination.

These data are identified instantly and without any human intervention, providing major time, efficiency and safety savings.

RFID applications and uses in the warehouse

When identifying, tracing and managing the product error-free in each logistics phase, RFID tags facilitate this work, as warehouses increasingly demand greater efficiency and agility. This system offers the warehouse infinite possibilities. Apart from the control of goods other processes such as the entry of trucks, handling equipment, etc. can be controlled too.

Stock management and GPS

It is ideal for correct control and storage of the warehouse stock, for example, a computer connected to RFID technology can see in real time throughout the whole warehouse whether the stock is about to run out or if it is at an optimum level, communicating this information to those responsible. The chips may also contain indicators for the purposes of better storage and a GPS for tracking.

Storage data

The great advantage of chips is that the information stored on them can be modified at any time. If the location of the product changes or if it is stored in a place at a necessary temperature, the chip will be able to detect whether this temperature changes to ensure it is always stored correctly.

Safety

Apart from using it for daily processes, it is essential to comment on the extra security provided by this technology for the warehouse. Risk of losses, delays or even theft can be avoided. Many companies apply this technology in their warehouse to minimise errors in the logistics processes and improve safety and reliability in their supply chain for their customers.

Advantages and benefits of RFID in a warehouse

RFID technology provides a wide variety of advantages for warehouses. Their operations improve if the processes are automated for increased profitability, resulting in labour and time savings.

Some of the main benefits of using RFID systems in a warehouse are:

Product customisation

Thanks to the data collected in the chip included in each product, the products can receive a customised and unique treatment. Accordingly, the information on each unit in movement in the supply chain is controlled and centralised at all times, simplifying decision-making.

Agility and time-saving

This technology significantly improves the efficiency of all processes compared to barcodes and other more traditional methods. Moreover, workers save time as product inventory is automated and faster. This would be one of the main benefits of RFID.

Automatic registration

When all the products in the warehouse are registered using this technology, the inflow and outflow processes, expiry, errors, etc. will be automatic. This speeds up the whole process reducing errors, from product selection through to shipment to the customer.

Tracking and traceability

The products will be under control at all times, and thanks to their built-in GPS it will be quick and simple to identify and locate the goods without the need for a visual line between the reader and the tag. In terms of traceability, in this publication we talk about the traceability systems for industrial racking.

If you need any rfid products ,please feel free to contact us.